Compressor Inspection in Switzerland

Compressor and pumps are two rotating equipments that carry fluids inside a plant or circuit.

Two of the most common compressor used in industry are centrifugal and reciprocating, depending on the duty they are involved. Also axial compressor and screw are used in some applications.

For testing, exists two reference standards API 617 for centrifugal compressors and API 618 for reciprocating compressors. In both documents there is a dedicated section for inspection requirements, but the client can decide the extention of the inspecting activities.

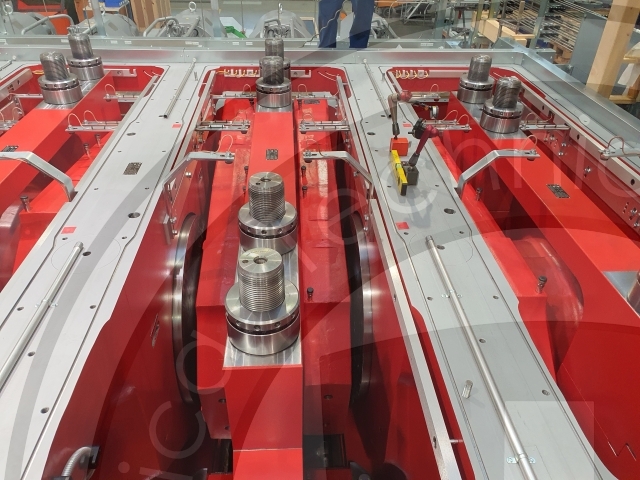

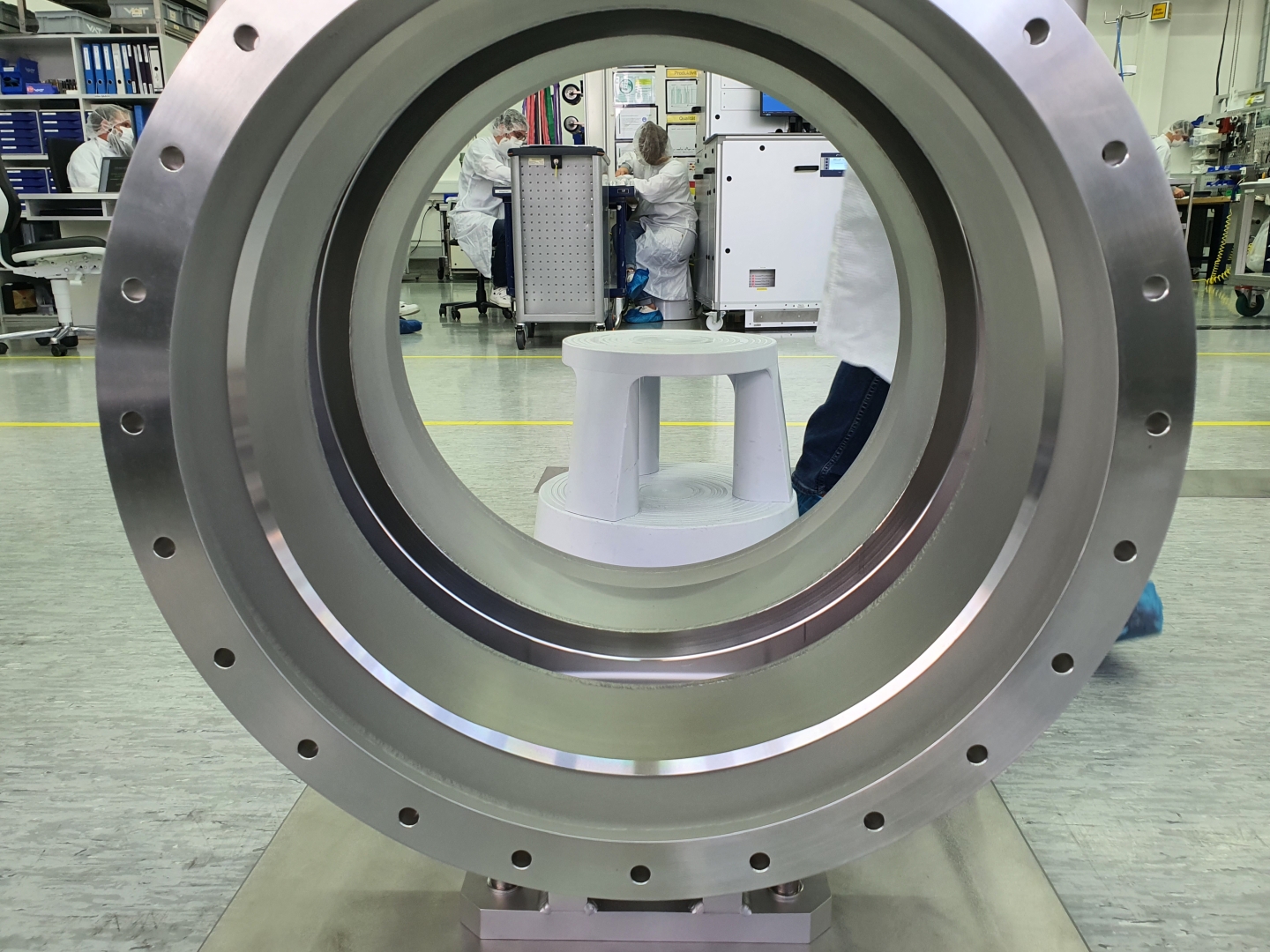

We as a company have a vast experience with inspecting compressors, both centrifugal and reciprocating whose have some activities in common and some specific for their category. Starting from the very beginning of the construction phase, we assisted hydrostatic pressure test of the casing, that can house the cylinder in case of reciprocating compressor or the impellers in case of centrifugal compressor.

Centrifugal Compressor

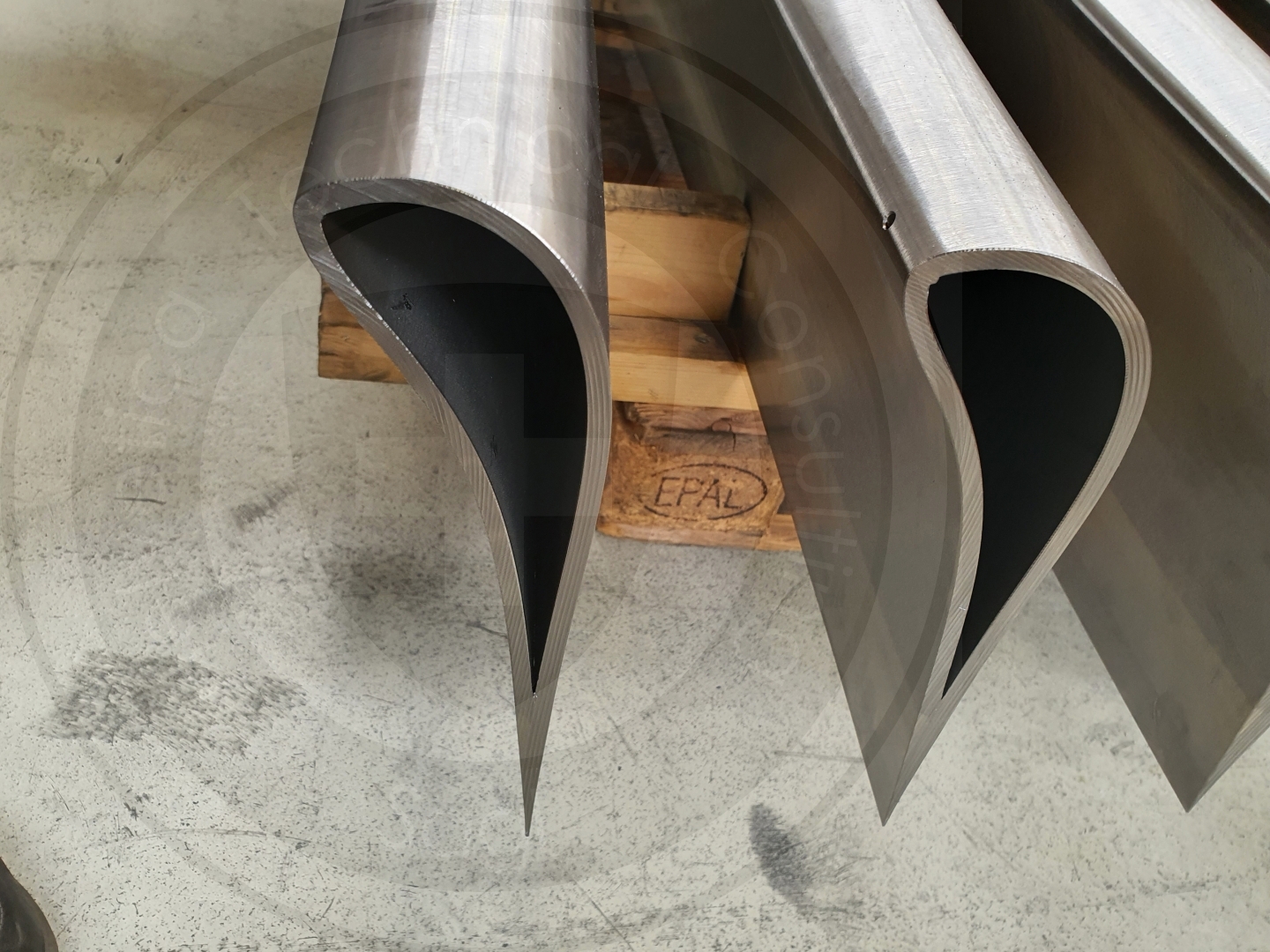

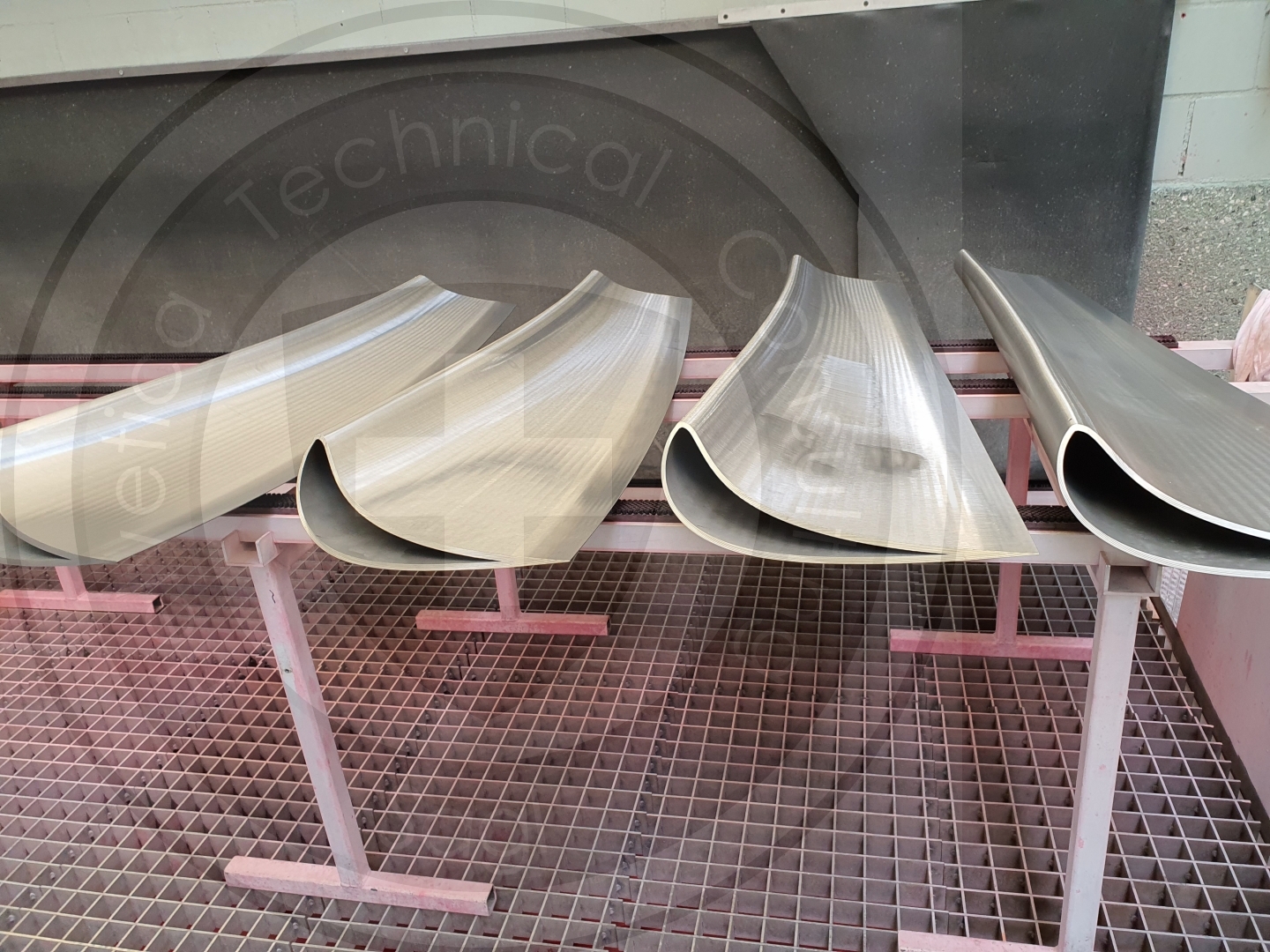

Successively overspeed and balancing of the impeller is key step in ensuring compressor performance. Assisting to this step is very important because allows to verify the fundamental frequency of the impeller which is important for maintenance and performance analysis.

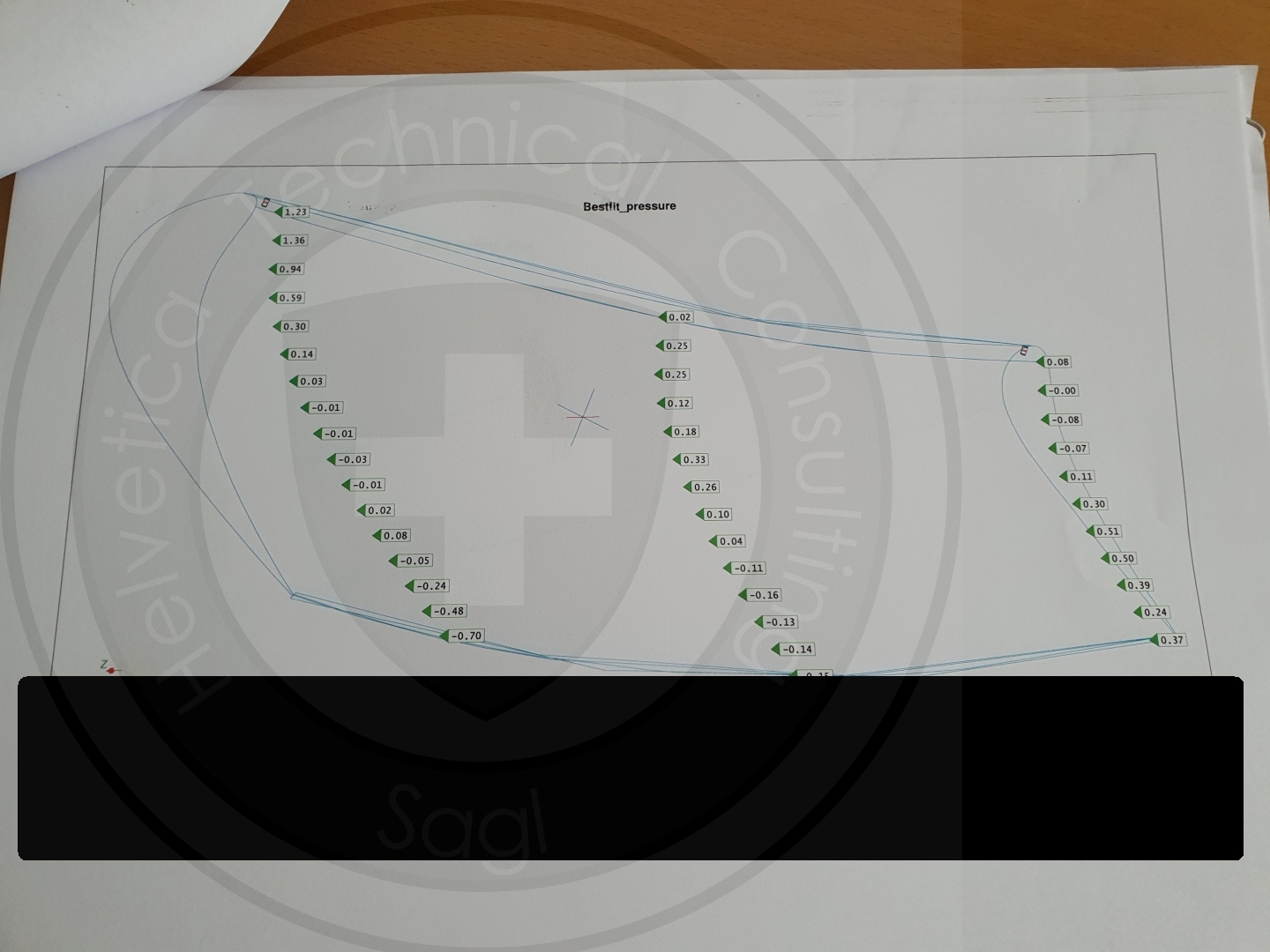

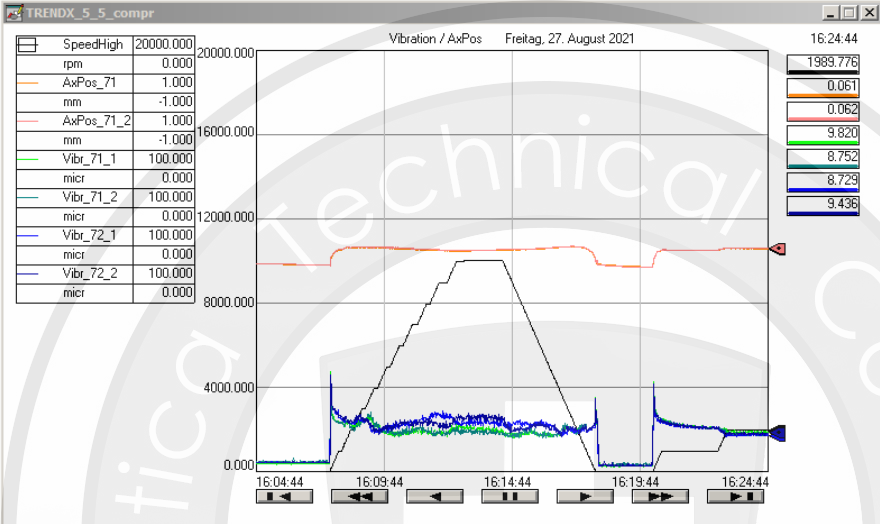

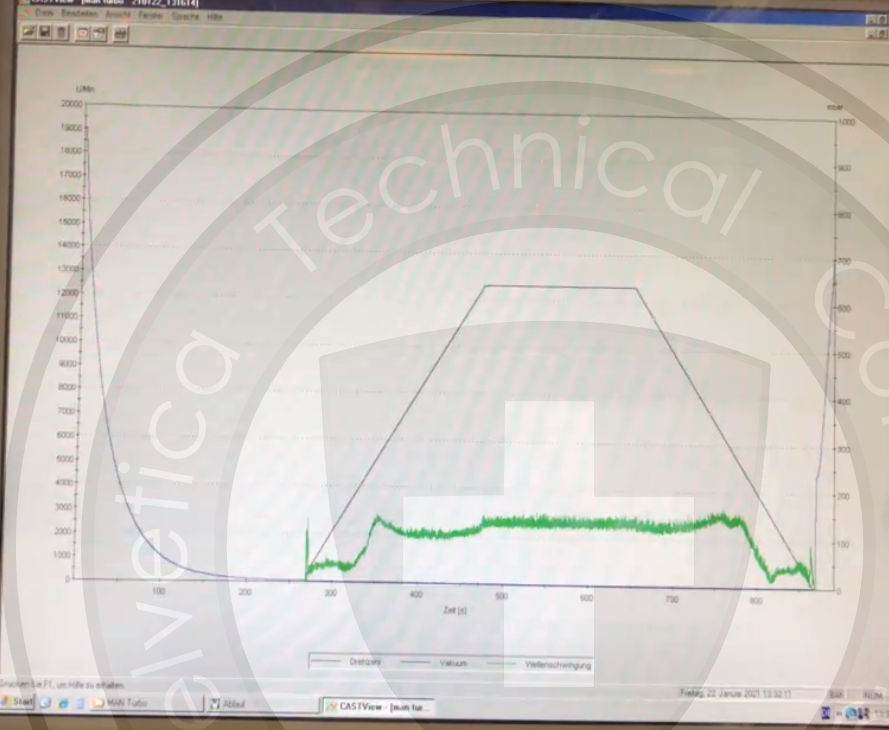

After balancing, performance and running test are performed. Performance test scope is to simulate process condition at supplier shop and determine the behaviour in terms of polytropic head and thermodynamic efficiency. To achieve this, there is a sequence of steps to follow in order to get the nearest result of the behaviour compressor can have under process condition.

On the other side, running test scope is to determine reliability/endurance behaviour of the compressor. After completion of both performance and running test, inspection of the bearings is done to verify wearing, scratches that are caused by tests.

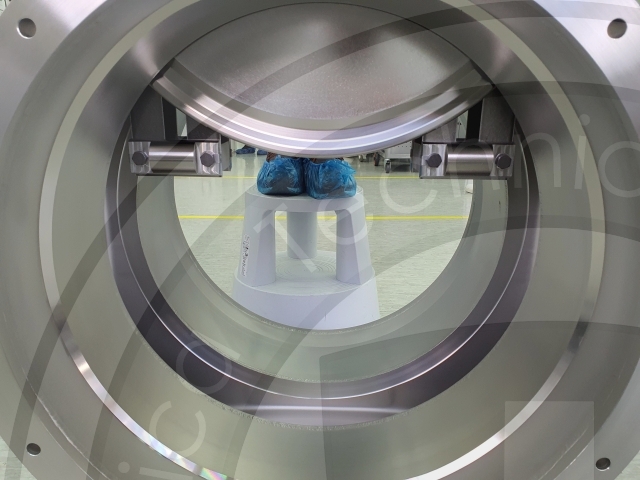

Final stage is assembly and final inspection.

Being based in Switzerland, we have the assignment to witness tests from the first step to the final stage, packing

Reciprocating compressor

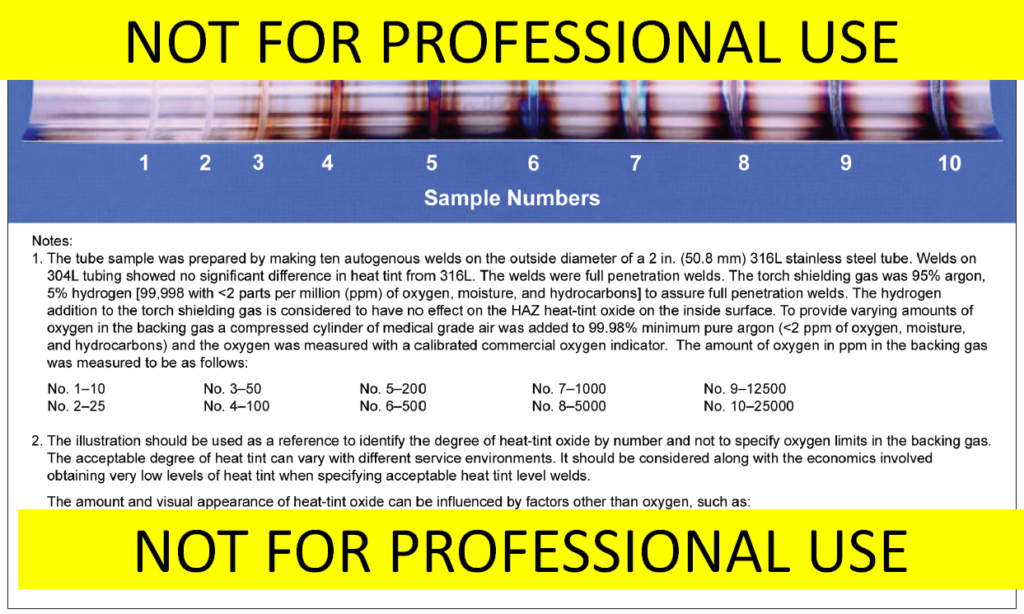

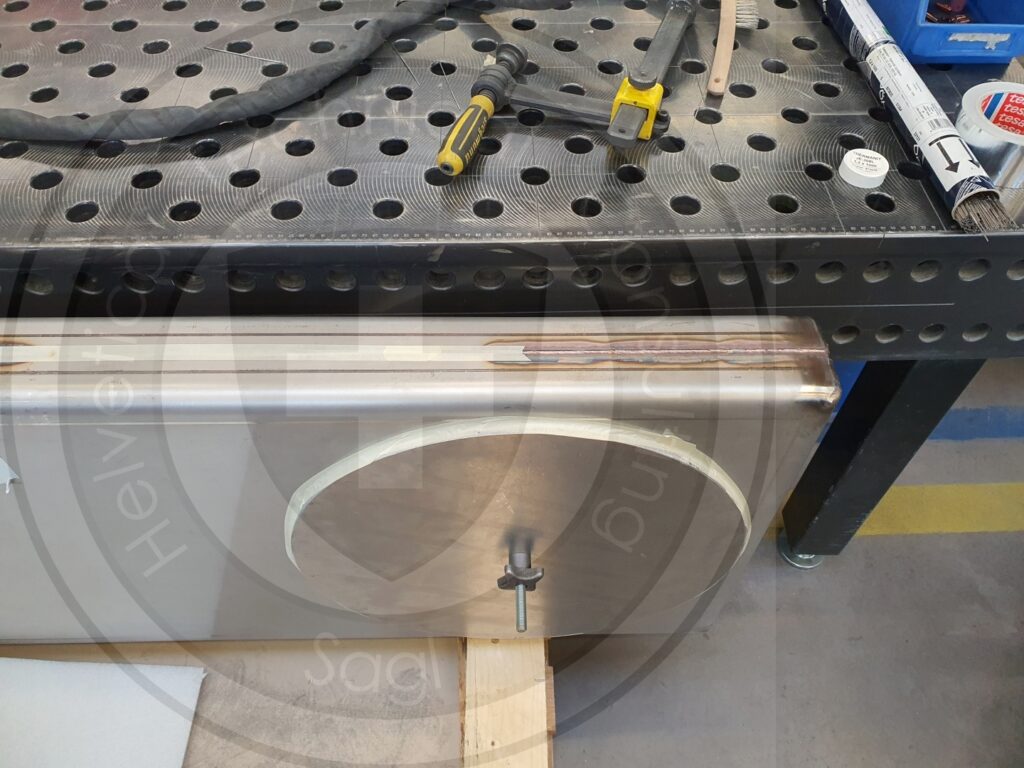

Reciprocating compressor inspection, starts with hydrostatic test of the casing that will house the cylinders. After hydrostatic, air & helium test are done to fully determine possible leaks.

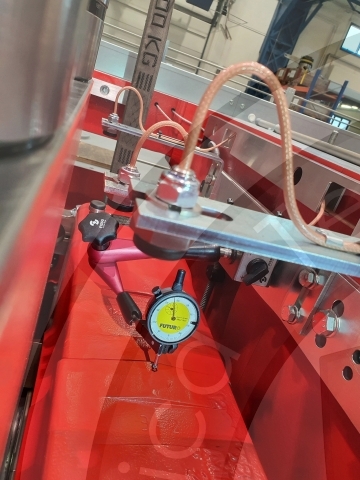

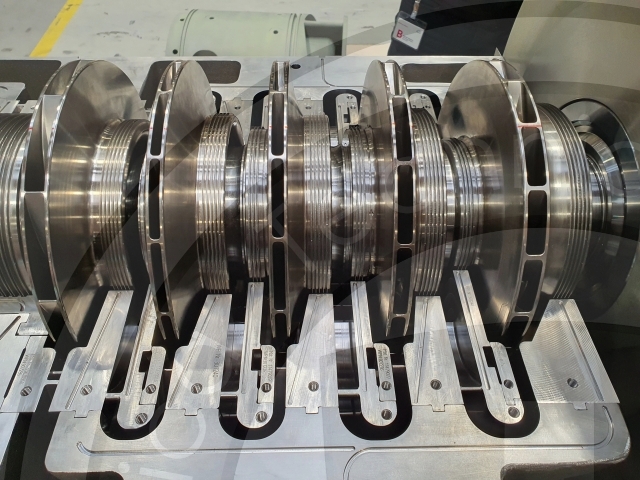

Performance test is a key step for evaluate compressor behaviour and also cylinder head inspection is needed. In contrast with centrifugal compressor, after running test, piston allignment need to be measured and verify if in tolerance.

Packing is the last activity to do by checking tools and spare parts provision.